Methane Emissions Reductions

We achieved our 99% gas capture target in 2022 and are on course to deliver on our commitment to zero routine flaring by 2030.

Since 2019, we have reduced methane emissions intensity and absolute methane emissions by 9% and ~20% respectively, marking our lowest methane intensity rate since 2014. This is primarily related to a reduction in instrument gas-driven pneumatic controllers and pumps, as well as a reduction in flaring. In early 2023, we began a biannual aerial survey program across all our domestic assets to further detect and reduce methane emissions.

- ᵃ U.K. assets divested in 2019.

- ᵇ Increase in 2020 was due to a counting discrepancy discovered during in-housing of the GHG inventory, and production decline.

- ᶜ When compared to historic performance, the profile of emissions sources shifted substantially due to focused efforts to reduce associated gas flaring in the Bakken. Increased percentages in other areas don’t reflect an increase in emissions from that source, rather a composition change over a smaller total emissions base.

Emissions Reduction Technologies

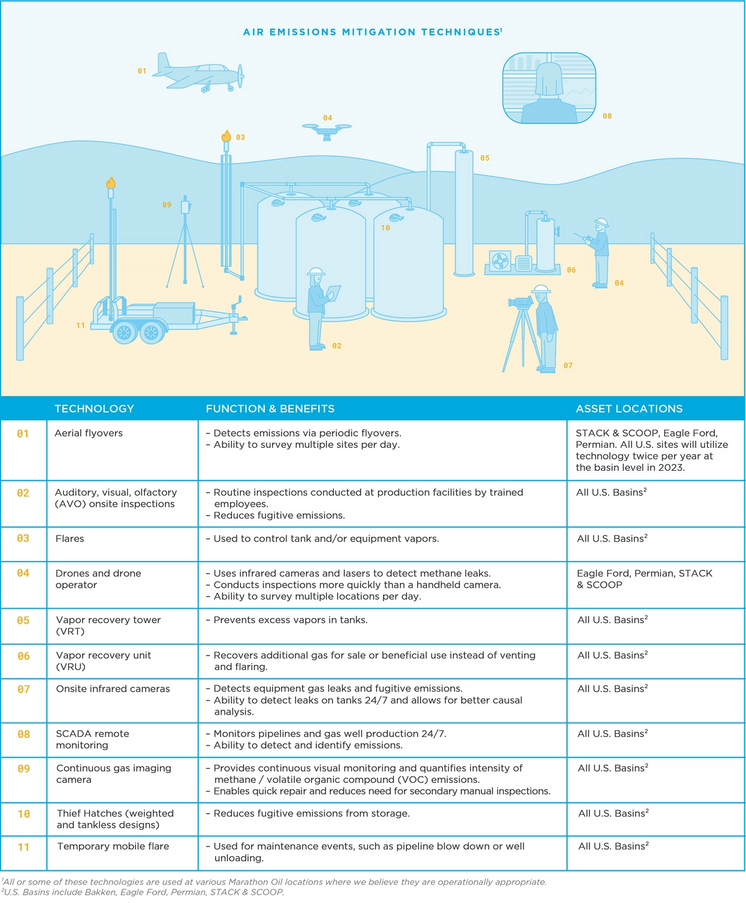

Our efforts to reduce methane intensity in our field operations are focused on best practices, new innovations, enhanced operations and technological advances around:

- Facility design and technological advances, including our lowest emitting automated facilities (LEAF) design, which is described in more detail below.

- Leak management and prevention.

- Flaring reductions.

- Electrification opportunities.

- Feasible renewable energy.

Our Emissions Management Committee guides asset level teams that identify, evaluate and execute our strategy of reducing operational emissions and utilizing innovative technology.

In 2021, we earmarked $100 million for emissions reduction projects over a five-year period. Over the past two years, a steering committee from across our U.S. assets has reviewed multiple proposals and implemented new methods of reducing emissions. The first of these is the conversion of gas-powered pneumatic controllers to instrument air or non-venting controllers that will permanently reduce emissions. Beginning in 2022, devices installed on company-owned equipment are non-venting. We also are utilizing renewable energy – installing solar panels on our facilities where feasible to power small use needs. In addition, we are actively investigating opportunities to electrify our compressors and connect our sites to utility power to reduce reliance on generators where possible. Total spend for 2022 includes:

- VRU installation: ~$8.2 million

- Instrument air/non-venting controllers: ~$6.5 million

- LEAF design: ~$2.4 million

- Electrification: ~$1.4 million

Designing Lowest Emitting Automated Facilities (LEAF)

In 2022, Marathon Oil reconceptualized our existing facility design with an aim to build the lowest emitting automated facility in our operations. We wanted to capture additional natural gas without compromising the safety and reliability of our operations — all while complying with or exceeding environmental requirements. The new design enables production of the same amount of oil, with little to no flaring, allowing us to capture and sell much of the gas that previously would have been flared. This operational approach delivers financial, production and environmental improvements.

We are committed to implementing LEAF design concepts across our U.S. assets. We launched prototype LEAF designs in the Bakken, Oklahoma and Permian in 2022 and we expect to develop new LEAF projects throughout 2023.

Methane Emissions Quantification and Measurement

We currently use EPA and API compendium source emissions factors applied to direct operational data from individual facilities to quantify our GHG and methane emissions. We view EPA and API protocols as the most comparable method for compiling a full annualized inventory and plan to continue to use these protocols for the near future.

There is stakeholder interest in estimating GHG and methane emissions through direct-measurement technology. However there are significant challenges with direct measurement of gasses in the atmosphere such as methane, especially from small or intermittent sources. Direct measurement involves the collection of single point flux measurements collected in an ambient atmosphere. Currently there are no commonly accepted standard protocols to incorporate atmospheric flux measurement into the quantification of emission factor-based inventories. Additionally, prevailing methane measurement technologies all contain significant error bars. There is currently no scientifically vetted methodology to sum this measurement data and provide a consolidated estimate of total emissions. Given the current state of measurement protocols and methane detection capability, we do not believe it is possible at this time to assess with confidence the differences between inventories developed using emission factor-based approaches and those based on direct measurement.

Our GHG inventory estimates that methane emissions are ~12% of our 2022 global Scope 1 emissions. We have conducted an assessment of the potential impact to our EPA factor calculated emissions inventory if actual methane emissions hypothetically were 50% and 100% higher than currently reported volumes. Under these assumptions, our overall Scope 1 GHG emissions in 2022 would have increased by 6.3% and 12.5%, respectively.

Reducing Flaring with Vapor Recovery

Capturing gas for sale or beneficial use over venting and flaring is a high priority at Marathon Oil. We install vapor recovery units (VRUs), which recover vapors in crude oil or condensate tanks at our facilities to help us recover additional gas for sale. In 2022, we spent $8.2 million retrofitting existing sites.

Use of Direct Measurement Technologies

While these direct measurement technologies are not yet useful for high-confidence quantitative data, we’re working to support practical implementation of them in our business to optimize emissions reduction efforts, find scalable options to lower emissions sources, troubleshoot at our facilities and highlight any knowledge gaps around our operations. Since 2018, we have tested multiple advanced methane detection and measurement technologies. These include drones, aerial surveys with varying technologies and fixed continuous monitoring devices. We have used these technologies in our U.S. resource plays supplied by various vendors. Details on these direct measurement technologies and where we are deploying them are provided below.

In 2023, we committed to a three-year basin-wide biannual flyover program of our domestic assets to detect and quantify methane emissions. This is our first resource-play-wide approach and is expected to provide us with a better understanding of our total methane emissions as viewed through quantification technology.

We will continue to prioritize methane emissions reductions by optimizing facilities and promoting pipeline integrity to reduce unintended methane emissions; removing sources of methane emissions such as gas-driven pneumatic controllers and pumps; and reducing flaring as we work towards our goal of zero routine flaring (World Bank definition) by 2030.

Reducing Leaks with Drones

As part of our emissions monitoring and equipment maintenance program, we utilize drone technology to monitor well pads. Flown by trained pilots, the drones’ leak-detecting cameras and lasers can conduct inspections more quickly than a handheld camera.

We automate drone flight imagery processing and use trained technicians to analyze the footage. This enables our maintenance and operations teams to quickly detect anomalies in well pads, has generated efficiencies in personnel time and helps the team to prioritize repairing leaks with the greatest emissions potential. Drones are one of our many emissions reduction technologies; see a more detailed list below.

Continuous Improvement and Validating Emissions Reporting

We are committed to continuing to improve our emissions estimates over time and validating our reported emissions estimates. We have undertaken efforts to document processes regarding inventory calculations, conducted field equipment inventory validations and held internal audits assisted by outside consultants to validate the accuracy and consistency of our processes. Additionally, we actively participate in industry and academic efforts to better understand and engage the EPA regarding the accuracy of its emissions factors. We will continue to learn and share best practices with our peers and engage in the public policy process to help improve industrywide methane management and estimation.

Further, our use of direct-measurement technology to identify and mitigate emissions is intended to enhance confidence in our emissions inventory reporting. We will also continue to trial and support direct measurement technologies as those technologies continue to develop.

Other Air Emissions

We aim to proactively limit other emissions from our operations by utilizing an approach that includes best practices and follows regulatory compliance. These include reducing volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur dioxide (SO2) and any other pollutants that could impact air quality near our operations.

How are we doing?

Your opinion matters. Please take a moment to let us know how useful you find the content on this page.

If you’d like to give us your feedback on the entire report, please fill out the complete survey for the 2022 report.