VP Todd Abbott Addresses Txoga-steer Energy Summit

I want to begin by acknowledging both TXOGA and STEER and the good work they do on behalf of our industry. You and your teams work tirelessly throughout the state to promote the benefits of our industry, and provide context on the issues. And I have to commend the STEER team who are out in communities delivering our message and talking to stakeholders at the grassroots level across the Eagle Ford. They’re representing us at the county fairs, at the rotary club meetings and high school events. You’re making a meaningful difference. Thank you!

Please note our forward-looking statements disclaimer.

I've been working in this industry for most of my career. As Marathon’s VP of resource plays south, I’m over both Permian and Eagle Ford. Today, I’m going to focus on the Eagle Ford.

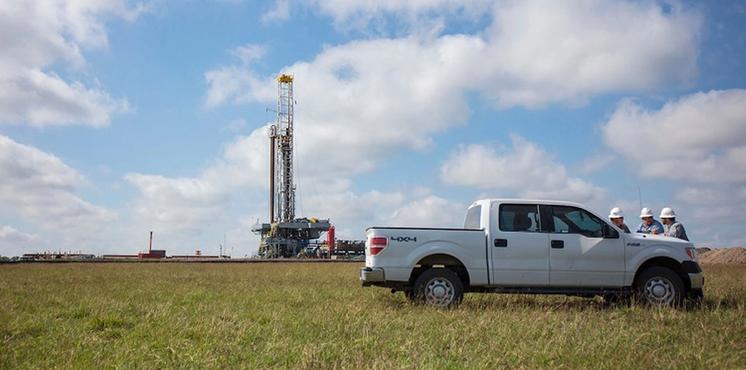

As many of you know, Marathon Oil has been on a transformational journey as a company. We entered the Eagle Ford the same year we became an independent – 2011. Today, more than 90 percent of our capital development budget is allocated to the U.S. resource plays. And, more than $700 million is allocated for our activity in the Eagle Ford, where we have four field offices in and around Bexar County, and over 1,500 producing wells averaging around 100,000 boe a day.

Just as we’ve transformed as a company, the Eagle Ford has also transitioned in many ways. For us the Eagle Ford became a free cash flow generator in 2017 as we’ve kept activity at maintenance levels while protecting economies of scale and enhancing efficiencies even further. About two-thirds of our wells to sales this year will be in the core Karnes County, and about one-third in Atascosa County. We’re expanding the core through continued improvement in well performance.

As we look back on the last couple of years, drilling efficiencies have played an important role in reducing our costs. Our incremental but steady improvement has been achieved through process optimization, the use of high-spec rigs and experienced crews, and numerous other small innovations. We’ve integrated new methodologies that include offline cementing, large multi-well pads, and more efficient walking packages on the rigs. All of these efficiencies allow us to spend more time drilling, more time on bottom turning to the right.

On the completions front, we’ve been very successful in reducing the time it takes to stimulate a well, while pumping higher stage counts with greater sand loadings per well. We’ve achieved this continuous improvement by upgrading our well casing designs, incremental improvements to equipment and technology, and by becoming much more efficient in sand handling.

On the production side, our focus has shifted to innovation and automation to improve artificial lift run times, improve overall production efficiency and reduce operating costs.

Within operations, we continue to leverage our digital oil field technology. An advanced SCADA and digital operating control center allows our field staff to “pump by priority,” lowering well site visits from almost daily to as low as once per month.

I’ve covered the gamut from drilling and completions to production operations. And that’s illustrative of where the Eagle Ford is in its life cycle today. Companies have transitioned from hyper growth … to efficient development and capturing cash flow from existing wells. There’s still a large remaining drilling inventory for companies to manage, but we also face the need to optimize a substantial base business. It creates a new dynamic for being a successful operator in this play.

We’re a results driven company, and how we achieve those results is equally important. Our employees place safety and integrity first in all we do.

It’s important for our industry that when concerns arise, we must address these topics in the right way, and with a sense of urgency. We must put them into context, engage openly and honestly with those who are voicing concerns, demonstrate our ongoing commitment to safe and responsible operations and be solution driven.

Safety, integrity, protecting the environment – we focus our talent and technology on these aspects of our business, just as we do on achieving high well productivity.

I’m proud to work in oil and gas, and to be here in Texas. When things were tough and the chips were down… operators, service companies, contractors and regulators have worked together to not only withstand this downturn over the last few years, but we continue to push for operational excellence.

Together we’ve built one heck of an oil field in south Texas and we’ll continue to build it, together, well into the future.

Thank you.